Auto & Motor Parts

- …

Auto & Motor Parts

- …

Custom Automotive Components Manufacturer

We engineer and manufacture precision automotive components and parts—from CNC-machined prototypes to die-cast aluminum production—for cars, trucks, and EVs. As an OEM & aftermarket automotive parts supplier, we deliver consistency, speed, and quality.

What We Make

Automotive Components & Parts We Supply

We design and manufacture a wide range of custom automotive components and parts for passenger cars, trucks, and EV applications. Each part is engineered for precision, durability, and performance under real-world conditions.

As a dedicated automotive components manufacturer, Wometal offers flexible production —from CNC-machined prototypes to die-cast aluminum parts— to meet OEM and aftermarket demands.

Our core product lines include:

Fuel & Cooling System Components

- Fuel Tank Caps / Oil Caps / Radiator Caps – CNC machined or die-cast aluminum for tight sealing and heat resistance

- Coolant Reservoir Caps / Washer Lids – Custom logos and colors available for aftermarket brands

Fasteners & Performance Hardware

- Wheel Nuts / Bolts / Spacers – Lightweight aluminum and steel options for motorsport and OEM use

- Quick Release Fasteners / Clamps / Fittings – Precision machined for racing and performance applications

EV Components & Thermal Management

- Battery Housings / Cooling Plates / Charging Connectors

High-pressure die-cast or CNC machined aluminum structures for lightweight and efficient EV designs - Heat Sinks / Cooling Modules for battery and power electronics

Trim & Interior Accessories

- Knobs / Handles / Decorative Covers with anodized finishes and custom branding

- Badges / Emblems / Caps for vehicle interior and exterior enhancement

🧠 Engineering Support

Whether you’re launching a new program or redesigning existing parts, our team provides DFM reviews, material selection, and surface finish consultation to optimize both performance and cost.

We serve OEM manufacturers, aftermarket brands, and industrial distributors worldwide.Explore our CNC Machining Capabilities and Die Casting Services for automotive components.

Capabilities

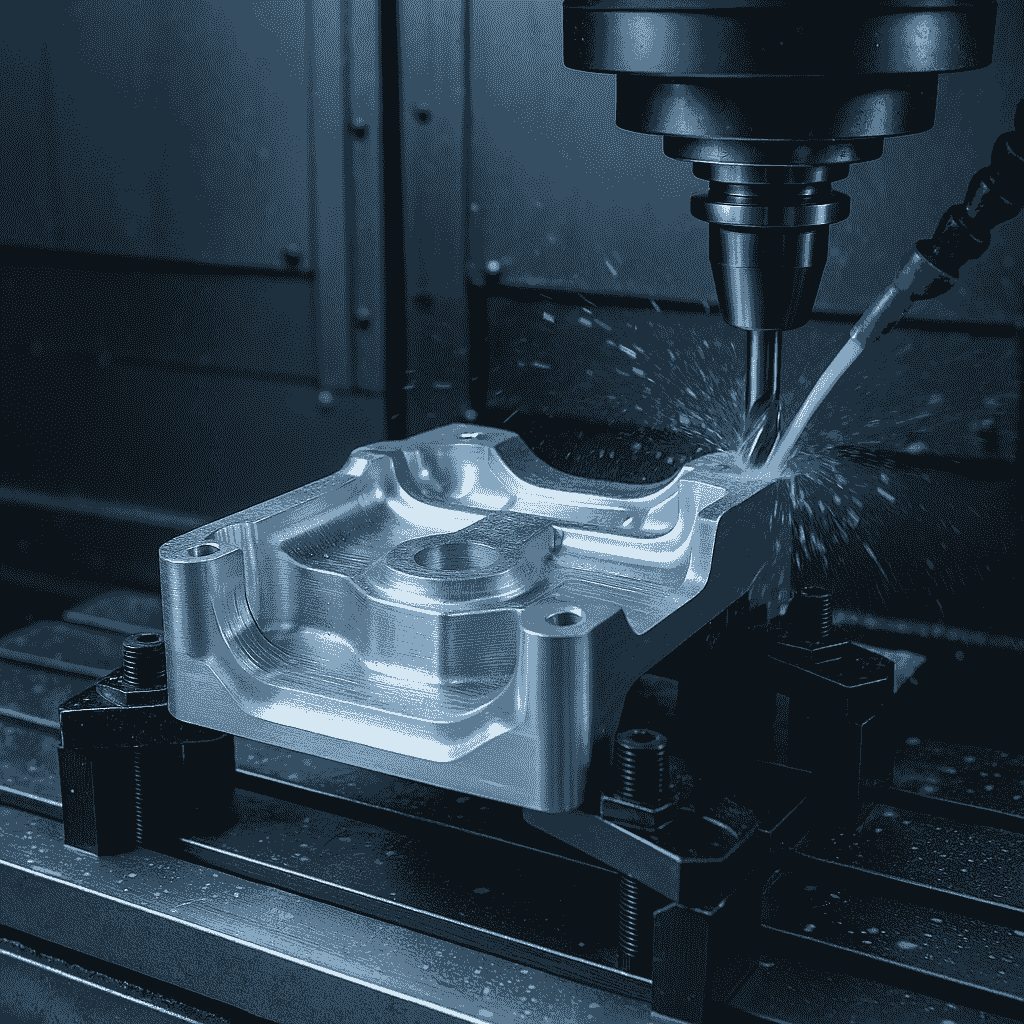

CNC Machining & Die Casting for Automotive Components

At Wometal, we combine CNC machining and die casting to produce precision automotive components with the strength, accuracy, and finish required for modern vehicles.From one-off prototypes to high-volume production, our processes are built around quality, consistency, and speed.

CNC Machining Capabilities

Our CNC machining workshops operate 3-axis to 5-axis centers for aluminum and stainless-steel components.

We specialize in:- Tight tolerance machining (±0.01 mm typical)

- Small-batch prototyping and custom low-volume production

- Turning, milling, drilling, and threading operations

- Precision automotive parts for chassis, cooling, and EV systems

Each CNC machined automotive component is inspected using digital calipers, micrometers, and CMM measurement systems to ensure accuracy and repeatability.

Die Casting Capabilities

Our die casting division produces high-strength, lightweight aluminum automotive components.

Capabilities include:- High-pressure die casting up to 800 T clamping force

- In-house mold design and optimization for better filling & ejection

- Post-machining, deburring, and surface finishing (anodizing, powder coating, polishing)

- Integration with CNC machining for critical tolerance areas

Engineering & Process Support

Every project begins with a DFM (Design for Manufacturability) review.

Our engineers work closely with customers to balance weight, cost, and mechanical performance.

We help optimize:- Part geometry and wall thickness

- Draft angles and fillets for die casting molds

- Tooling life and process stability

- Surface finishing and assembly compatibility

Surface Finishing Options

We provide a complete range of finishing services to enhance performance and aesthetics:

- Anodizing / Hard Anodizing (for corrosion resistance & appearance)

- Powder Coating / Painting

- Polishing / Bead Blasting / Sandblasting

- Laser Marking / Custom Logo Engraving

These finishing processes make our automotive components and parts ready for both OEM and aftermarket markets.

Materials & Lightweight Design

Lightweight Aluminum Automotive Components

Modern vehicles demand lighter, stronger, and more efficient parts.

At Wometal, we focus on lightweight aluminum automotive components that combine excellent mechanical strength, heat dissipation, and corrosion resistance.We also work with stainless steel, zinc alloy, and engineering plastics for applications where specific strength or appearance is critical.

Our engineering team selects the most suitable material based on load requirements, operating temperature, and surface finishing needs.⚙️ Material Options

🧩 **Aluminum (6061 / 6063 / 6082 / ADC12)**

**Typical Use:** Caps, housings, fasteners, cooling plates

**Advantages:** Lightweight, corrosion resistant, thermally conductive

🔩 **Stainless Steel (304 / 316)**

**Typical Use:** Structural and engine components

**Advantages:** High strength, heat resistance

⚙️ **Zinc Alloy (Zamak)**

**Typical Use:** Decorative covers, knobs, badges

**Advantages:** Excellent surface finish & dimensional stability

🧠 **Engineering Plastics (POM / PA / PC)**

**Typical Use:** Interior & functional parts

**Advantages:** Low weight, smooth feel, cost-effective

💡 Lightweight Design Optimization

We apply Design for Lightweighting principles to reduce part weight without compromising function:

- Geometry optimization using ribbing and hollowing

- Wall thickness reduction via DFM simulation

- Combining die casting and CNC post-machining for hybrid designs

- Integrating multiple functions into a single aluminum part

These improvements help customers meet stricter fuel efficiency and EV range targets while lowering production costs.

🌈 Surface Finishing for Materials

Every surface treatment enhances protection and appearance:

- Anodizing / Hard Anodizing – ideal for aluminum automotive components

- Powder Coating / Painting – for durable decorative finishes

- Polishing / Bead Blasting – improves surface texture

- Laser Engraving / Branding – adds custom logo or serial number

Quality & Inspection

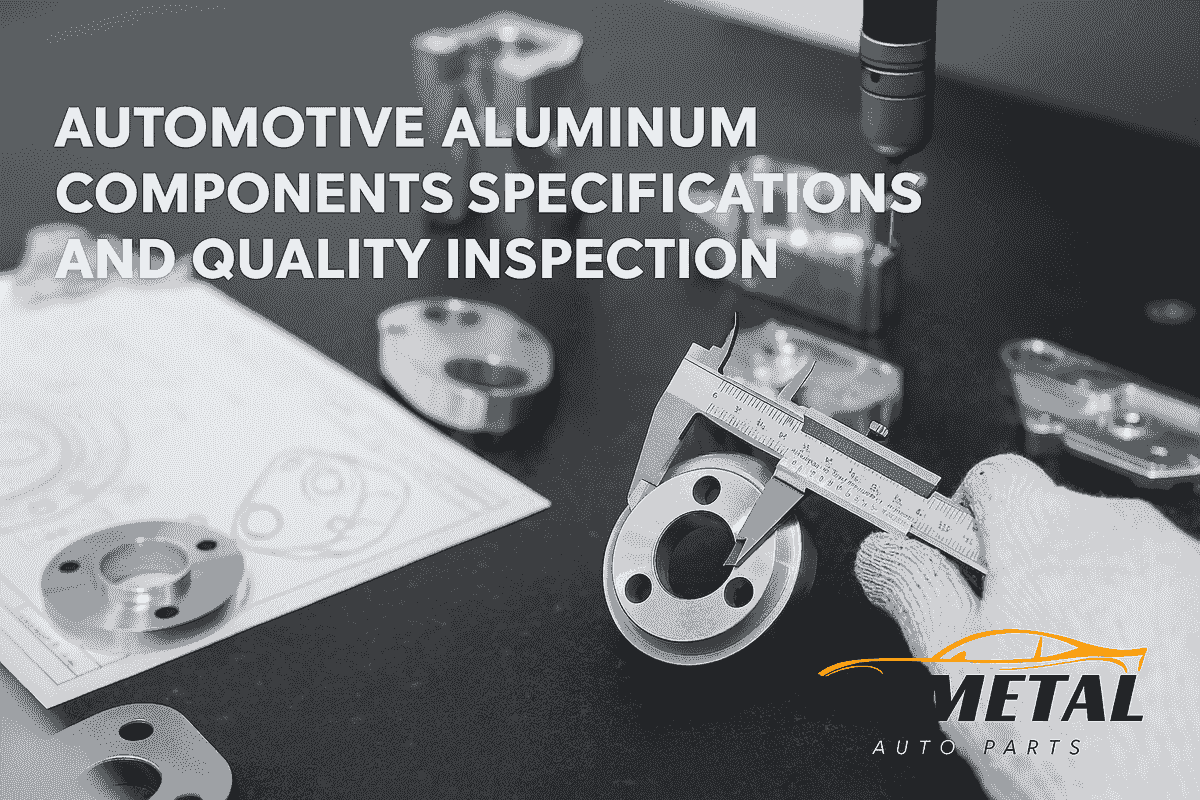

Quality Inspection for Automotive Components

Every automotive component we manufacture undergoes strict quality inspection to ensure precision, safety, and reliability.

From CNC machining to die casting, our quality control process tracks every stage—from raw materials to final shipment—guaranteeing that every part meets your drawing and tolerance requirements.

Learn more about our CNC Machining Capabilities and Die Casting Process,or explore our Surface Finishing & Quality Control details.

Our Quality Assurance Process

We apply ISO-based inspection routines and traceability for every production batch:

- Incoming Material Verification – alloy composition, certificates, and hardness check

- In-Process Inspection – dimensional measurement and SPC during machining

- Final Inspection – 100% visual and functional check before packing

- CMM Measurement – 3D coordinate inspection for tight-tolerance automotive components

- Documentation – COC, PPAP (on request), and RoHS/REACH compliance

Tools & Instruments

We use professional inspection and measurement tools for precision verification:

- Coordinate Measuring Machine (CMM)

- Digital calipers & micrometers

- Surface roughness tester

- Thread gauges & plug gauges

- 3D optical measurement system

Why It Matters

Consistent quality builds long-term trust.

By maintaining strict tolerance control and traceable quality data, we help OEM and aftermarket customers reduce rework, shorten lead times, and ensure stable supply across global projects.Applications & OEM Supply

Automotive Components for Cars, Trucks & EVs

Our automotive components are used across a wide range of vehicles — from passenger cars and commercial trucks to electric vehicles (EVs) and heavy-duty machines.

We understand that each sector demands different materials, tolerances, and surface finishes.Whether it’s CNC-machined aluminum parts for precision assemblies or die-cast housings for EV battery systems, we deliver solutions that meet strict OEM and aftermarket requirements.

- Passenger Cars – interior & exterior components, fuel & cooling caps, trim covers

- Commercial Trucks – high-durability aluminum fasteners, cooling modules, and housings

- Electric Vehicles (EVs) – battery housings, cooling plates, charging connectors, and heat sinks

- Heavy Equipment – rugged metal parts for construction and industrial machinery

Industries We Serve

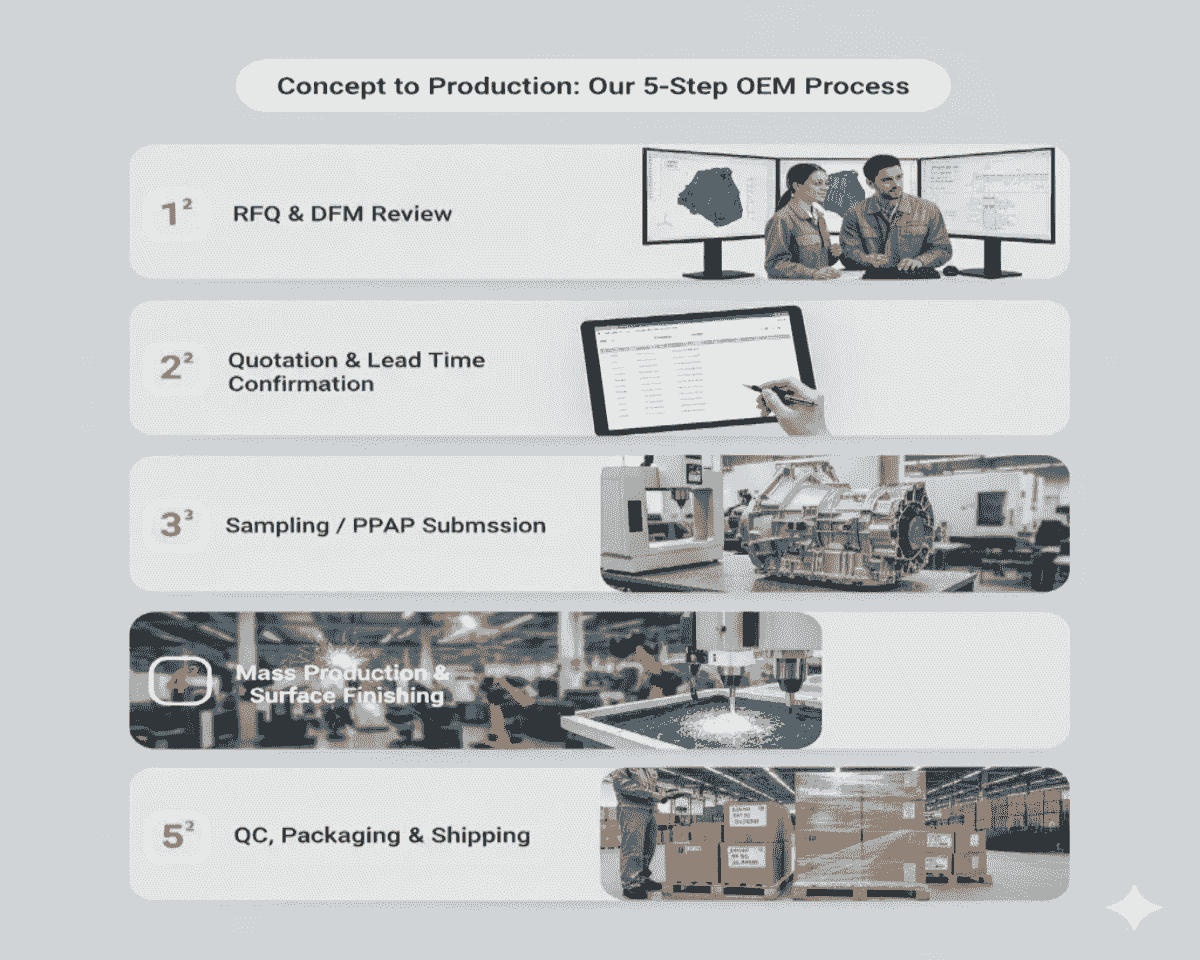

As an OEM automotive parts supplier, we provide complete support from concept to production.

Our process ensures reliability, transparency, and quick turnaround:1️⃣ RFQ & DFM Review – evaluate manufacturability and suggest design improvements

2️⃣ Quotation & Lead Time Confirmation – transparent cost structure and realistic delivery

3️⃣ Sampling / PPAP Submission – validation and dimensional approval

4️⃣ Mass Production & Surface Finishing – strict process control and inspection

5️⃣ QC, Packaging & Shipping – export-ready logistics and documentationOEM & Aftermarket Supply

- Engineering support for DFM and cost optimization

- Full material traceability and quality documentation

- Flexible MOQs (from prototype to mass production)

- On-time delivery for global programs

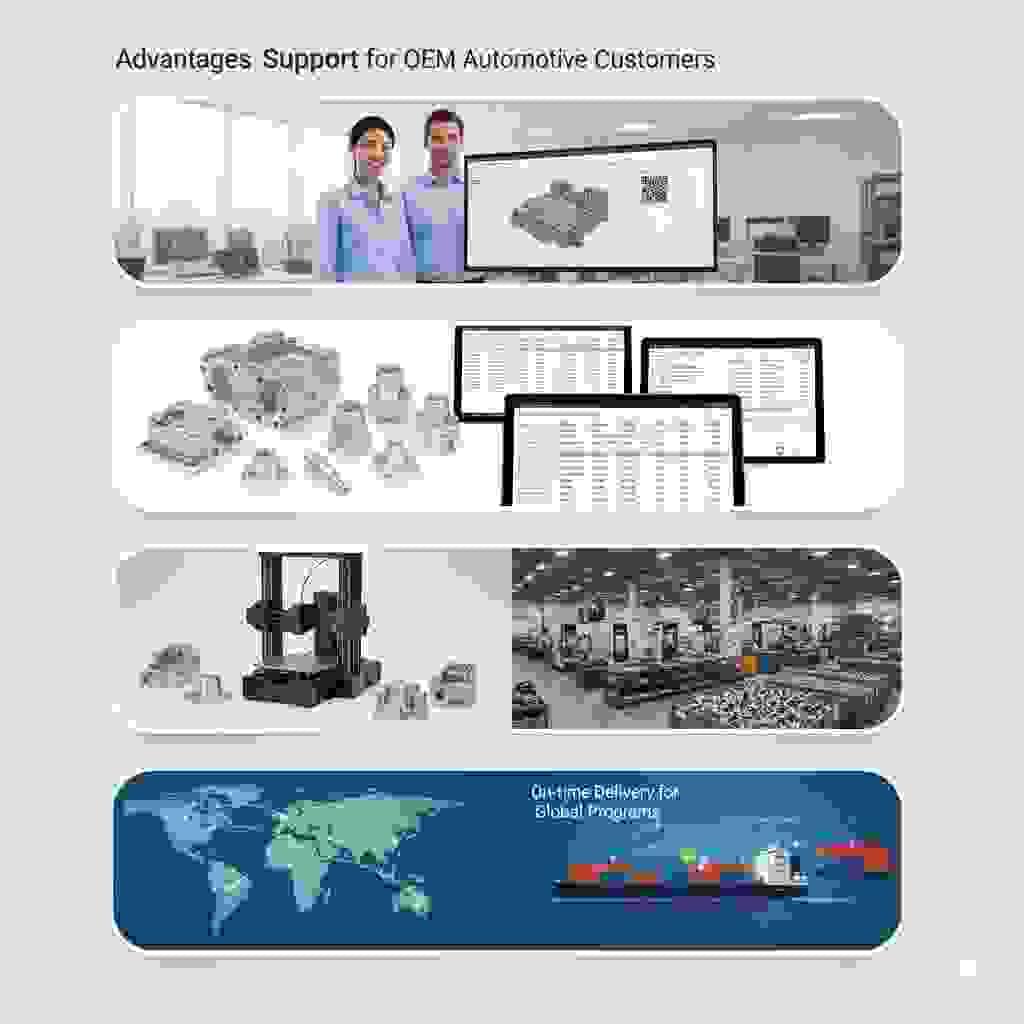

Advantages for OEM Customers

Customer Examples

Our products are used in cars, trucks, buses, electric vehicles, motorhomes, and racing cars, supporting both OEM programs and aftermarket brands.

These case studies show how Wometal helps global customers design and manufacture precision automotive components that combine performance, durability, and lightweight design.

Aluminum Fuel Tank Cap for Bus Application

A bus manufacturer required a durable and lightweight aluminum fuel tank cap to replace their traditional steel version, aiming to improve corrosion resistance and reduce overall vehicle weight.

Our Solution:

We developed a custom aluminum fuel cap using a combination of die casting and CNC machining.

The housing was cast in ADC12 aluminum and then CNC finished for precise thread fit and sealing performance.

Surface treatment included hard anodizing for enhanced corrosion resistance under outdoor and humid operating conditions.Results:

- Weight reduced by 30% compared to the original steel cap

- Improved fuel sealing reliability and corrosion resistance

- Design validated through pressure and vibration tests for public bus applications

This project is now in regular supply to several commercial and electric bus platforms, helping our customers achieve better fuel efficiency and product lifespan.

Frequently Asked Questions

Q1: What are automotive components?

Q2: What’s the difference between CNC machining and die casting?

Q3: Do you supply both OEM and aftermarket customers?

Q4: What materials do you offer?

Q5: How long does it take to produce custom automotive components?

Q6: How can I request a quotation?

Get a Quotation for Your Automotive Components Project

Looking for a reliable automotive components manufacturer?

Upload your drawings and tell us your requirements — our team will review, suggest process options, and send you a detailed quotation with lead time and cost breakdown.To prepare an accurate quotation for your automotive aluminum components, please include the following details in your inquiry:

✅ Drawings & Files — 2D / 3D drawings (STEP, STP, PDF, DWG, etc.)

✅ Material & Finish — e.g. Al 6061 + black anodizing, ADC12 + powder coating

✅ Critical Dimensions & Tolerances — specify key fits or inspection points

✅ Quantity & Batch Size — prototype, small, or medium production

✅ Application Area — e.g. engine housing, EV cooling plate, interior trim

✅ Quality Requirements — CMM reports, PPAP, coating tests, etc.

✅ Target Lead Time & Shipping AddressOnce we receive your information, our team will review your drawings and respond within 24 hours with a full quotation and manufacturability review.

💬 Ready to discuss your project? Contact our engineers →

Related Articles

November 10, 2025November 10, 2025November 10, 2025November 9, 2025November 9, 2025November 10, 2025November 9, 2025November 10, 2025November 10, 2025November 9, 2025

OUR PRODUCTS

- Fuel & Cooling Caps

- Wheel Fasteners

- EV Component

- Control Parts

- Badges & Decorative Parts

- Quick Release & Racing Parts

CONTACT US

Email: lisa@

Tel: +86 13810563840

Whatsapp/Wechat:

+86 13810563840

News

OVER 20 YEARS OF EXPERIENCE IN ALUMINUM PARTS

Global Export Capability | Fast Response | OEM/ODM Ready | Engineering Support

Wometal is a manufacturer of CNC machined and die-cast aluminum components for automotive, racing, motorcycle and EV applications.

We produce custom aluminum parts including fuel caps, engine covers, spacers, reservoir caps, cooling caps and precision components for global brands and aftermarket companies.