Auto & Motor Parts

- …

Auto & Motor Parts

- …

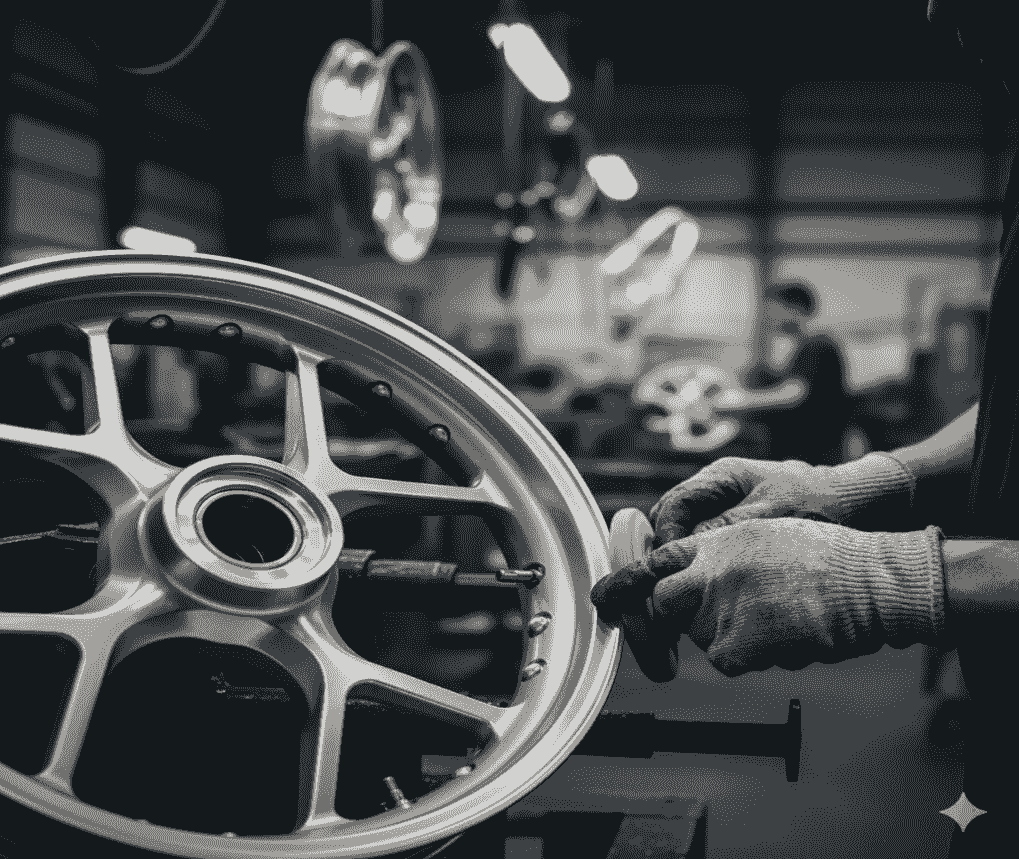

Metal Surface Finishing for Automotive & Motorcycle Parts

Anodizing, powder coating, polishing and bead blasting—consistent color, durability and premium appearance for aluminum components.

Complete Surface Finishing Solutions

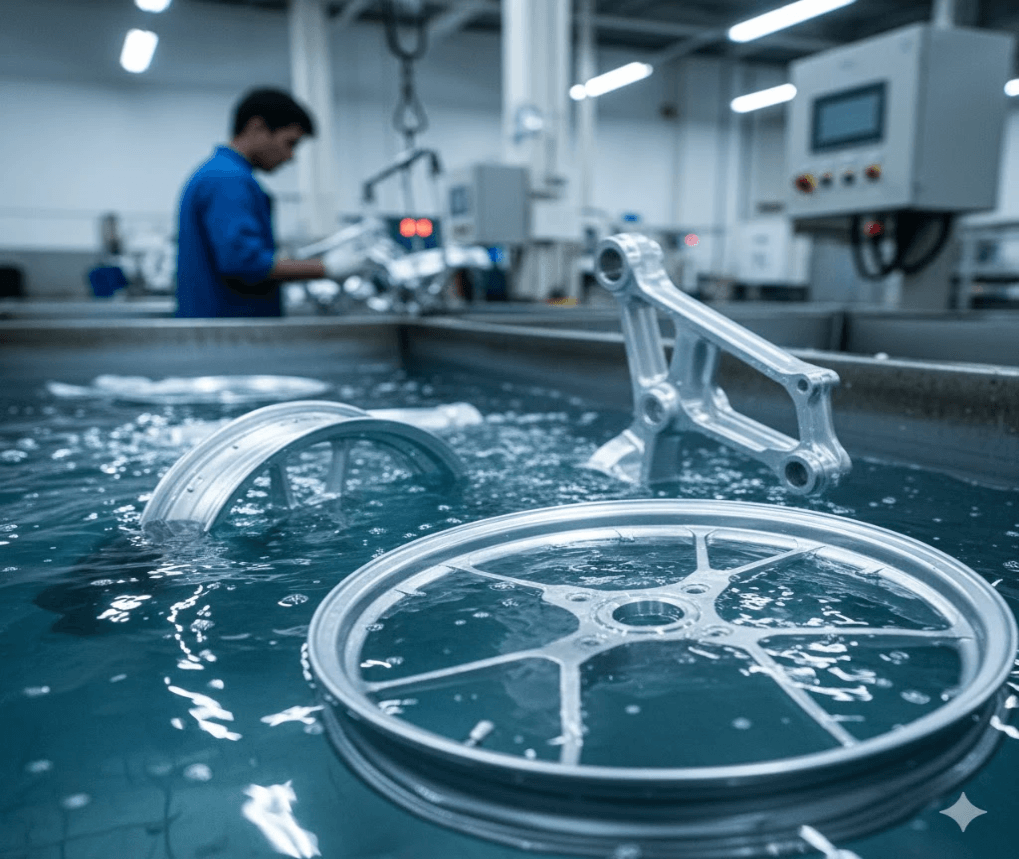

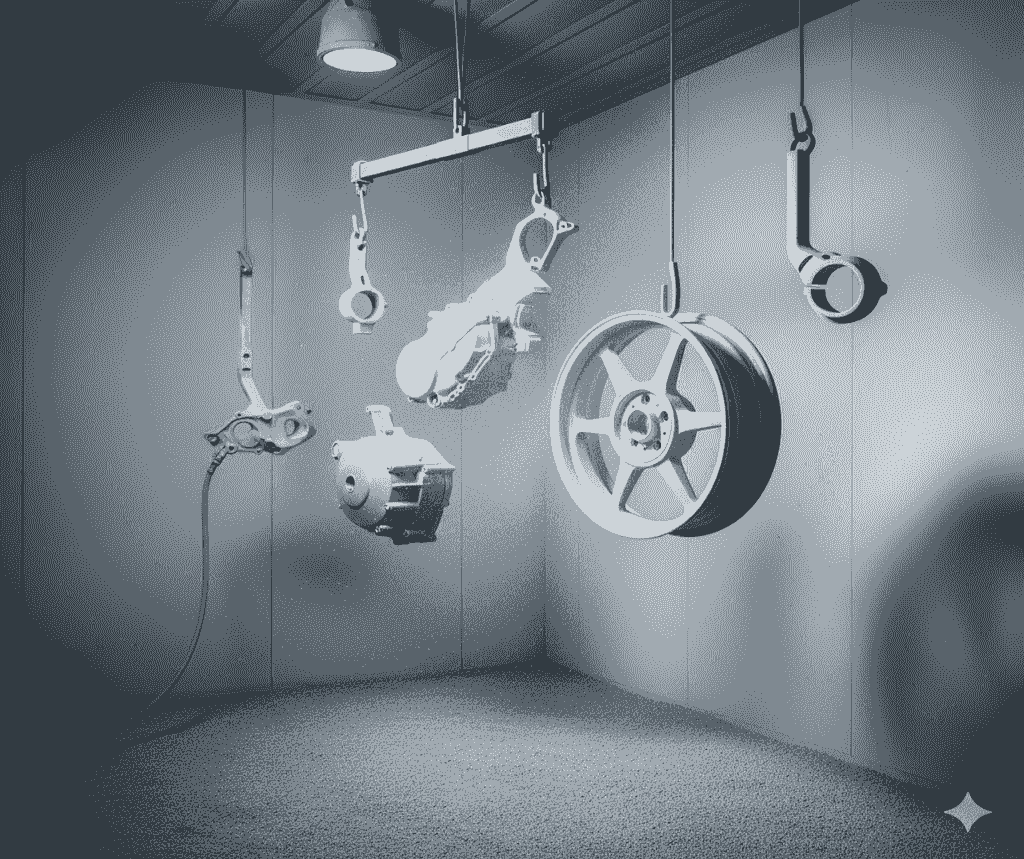

At Wometal, we provide comprehensive surface finishing services for aluminum and stainless-steel parts produced by our in-house CNC machining and die casting lines.

By integrating these processes under one roof, we ensure each part receives a consistent finish — from precision machining to final coating — with tight control over quality and color.Our finishing capabilities include:

- Anodizing (Type II / Type III) – corrosion resistance and color stability for visible components

- Powder Coating – durable, uniform coating for harsh environments

- Polishing – brushed or mirror surface for premium appearance

- Bead Blasting – smooth matte texture for a refined feel

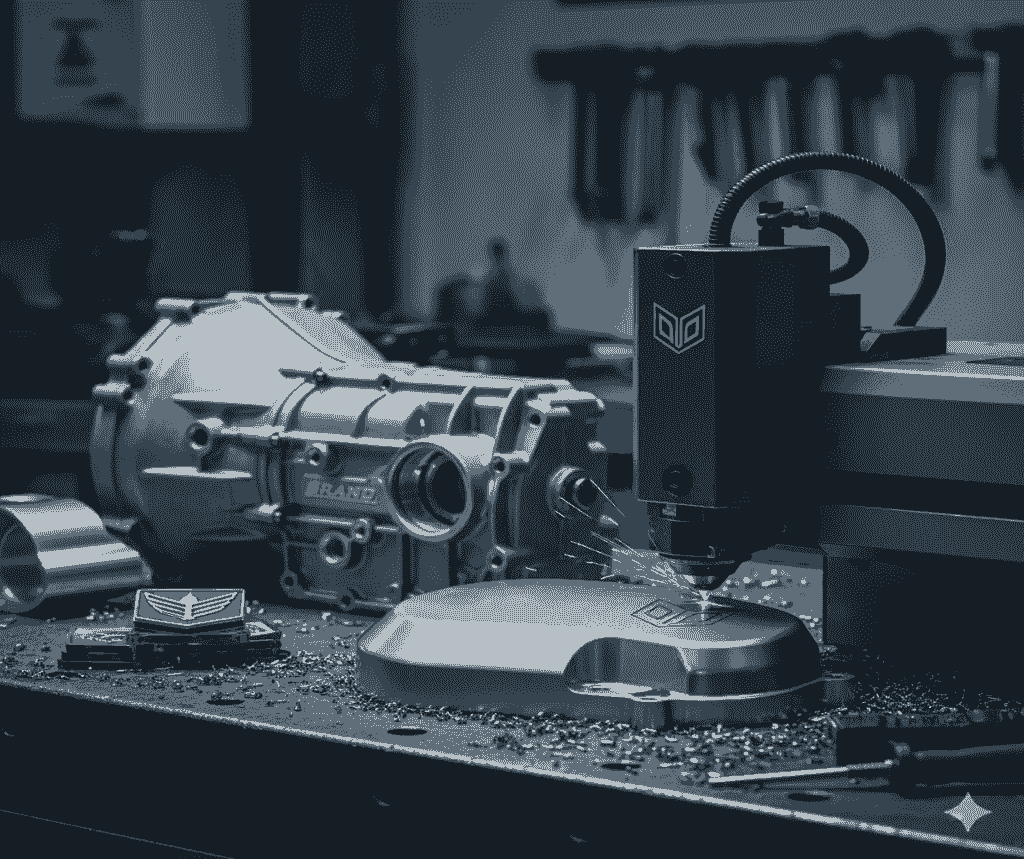

- Laser Marking & Branding – add custom logos or part numbers

Every finished component is fully inspected for adhesion, color, and surface texture before shipment, ensuring it meets both engineering and aesthetic requirements for automotive and EV applications.

Finishing Processes

Anodizing (Type II / III)

Color-stable, corrosion-resistant, suitable for visible parts.

Colors: black, clear, red, blue, gold (custom on request).

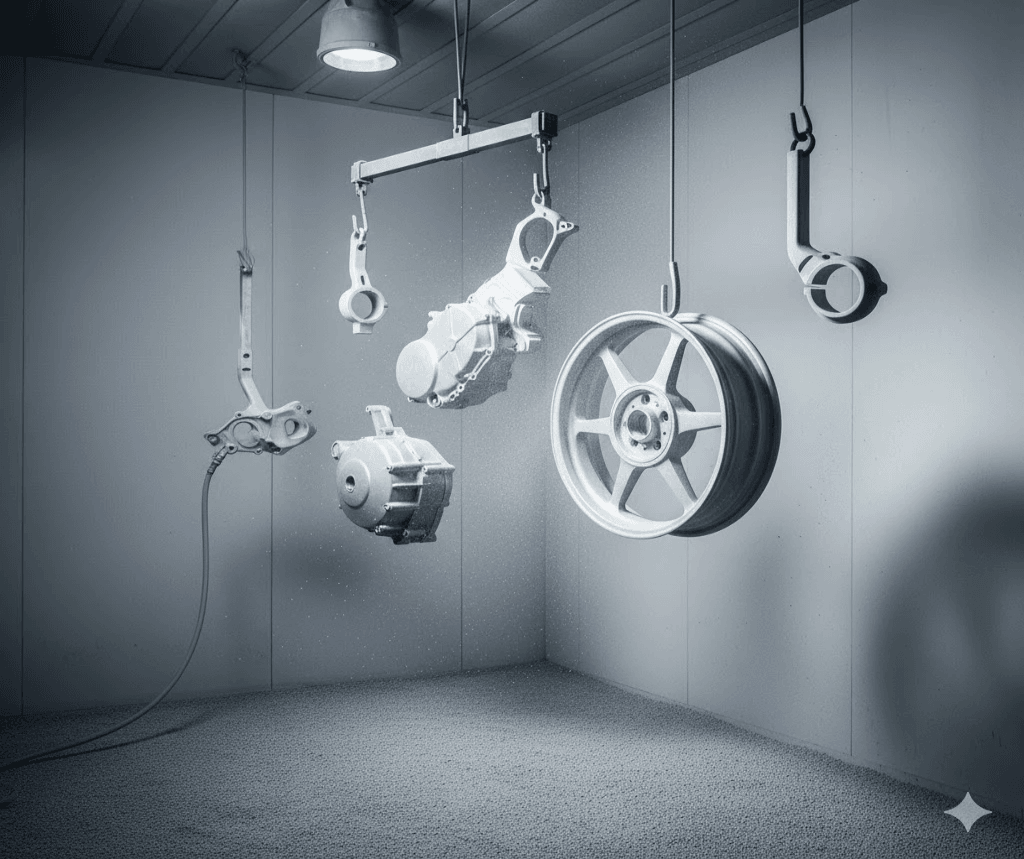

Powder Coating

Thick, durable coating; smooth or textured; outdoor-grade options.

Polishing

Brushed or mirror finish for premium appearance

Bead Blasting

Fine matte surface, hides machining marks, ideal under anodizing.

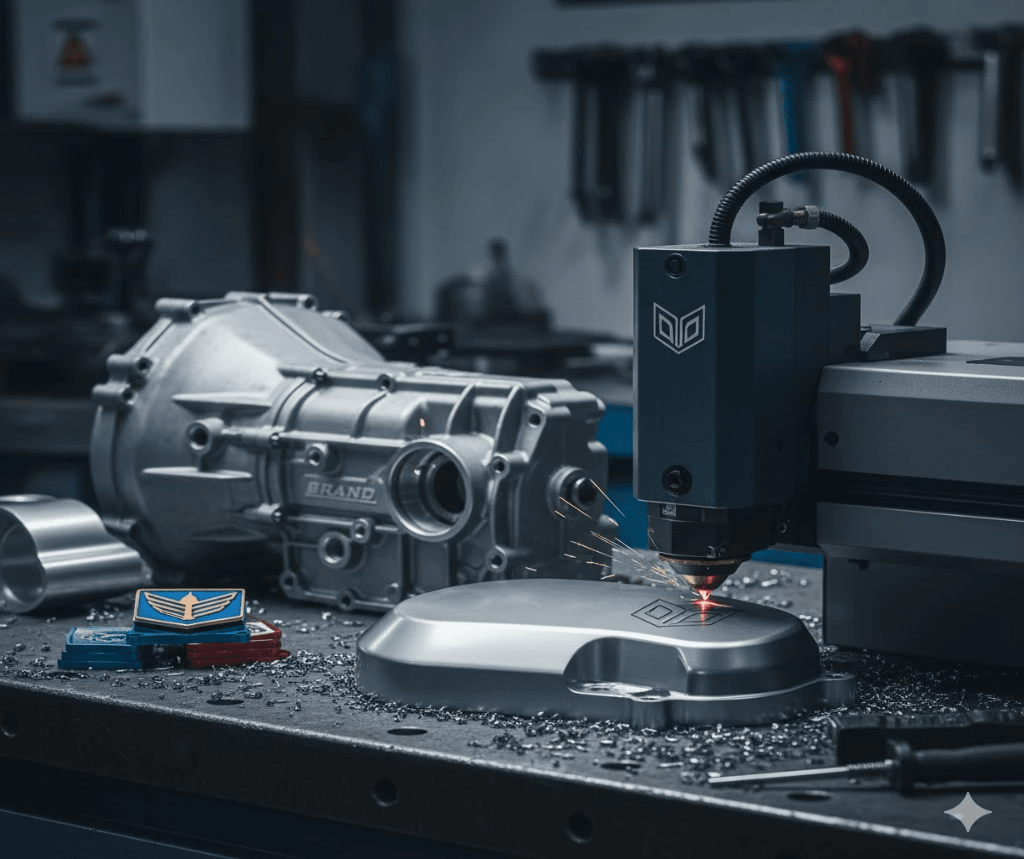

Branding & Marking

Laser marking, engraved logos, custom color badges.

Consistency & Quality Control

At Wometal, surface quality isn’t treated as a final step — it’s built into every stage of production.

From die casting to CNC machining and final finishing, all processes are managed under one quality system to ensure dimensional accuracy, coating thickness, and color consistency across every batch.We perform:

- Adhesion and hardness testing for anodized and coated surfaces

- Color and gloss measurement to ensure visual uniformity

- CMM and dimensional verification from our CNC machining inspection data

- Surface roughness checks (Ra ≤ 0.4 μm typical)

- Batch traceability and process records for full production visibility

This integrated quality approach ensures that every part — whether cast, machined, or finished — meets the high standards required for automotive, EV, and industrial applications.

Industries We Serve

Our surface finishing services support a wide range of applications — from visible aluminum trims in cars to durable, color-stable components for electric vehicles and motorcycles.

Automotive

Visible interior knobs, exterior trims and housings.

Motorcycle & Racing

Fuel caps, levers, pedals and decorative parts.

EV & New Energy

BBattery housings, thermal components and brackets.

Industrial Equipment

Precision covers, handles and connectors.

Upgrade Your Parts with Premium Finishes

Get samples or send drawings—our team will advise the best finish for performance and appearance.

What’s the Difference Between Anodizing and Powder Coating?

Anodizing changes the aluminum surface at a micro-structure level, keeping a metallic look and improving corrosion resistance. Powder coating adds a thicker protective layer with strong color coverage and chip resistance. We’ll recommend the best option based on your part geometry, application and budget.

OUR PRODUCTS

- Fuel & Cooling Caps

- Wheel Fasteners

- EV Component

- Control Parts

- Badges & Decorative Parts

- Quick Release & Racing Parts

CONTACT US

Email: lisa@

Tel: +86 13810563840

Whatsapp/Wechat:

+86 13810563840

News

OVER 20 YEARS OF EXPERIENCE IN ALUMINUM PARTS

Global Export Capability | Fast Response | OEM/ODM Ready | Engineering Support

Wometal is a manufacturer of CNC machined and die-cast aluminum components for automotive, racing, motorcycle and EV applications.

We produce custom aluminum parts including fuel caps, engine covers, spacers, reservoir caps, cooling caps and precision components for global brands and aftermarket companies.