Auto & Motor Parts

- …

Auto & Motor Parts

- …

Engineering & Quality Support for Custom CNC & Die-Cast Components

From drawing review to CMM inspection, we help ensure precision, consistency, and reliable manufacturing for automotive, motorcycle, and EV components.

What We Provide

DFM Review

Optimize structure, tolerance, strength & manufacturability.

CMM Inspection

High-precision dimensional accuracy for critical components.

Tolerance & Fitment Control

Ensure perfect fit for threads, sealing areas, and assemblies.

Material & Surface Support

Guidance on material selection, finishing, and anodizing quality.

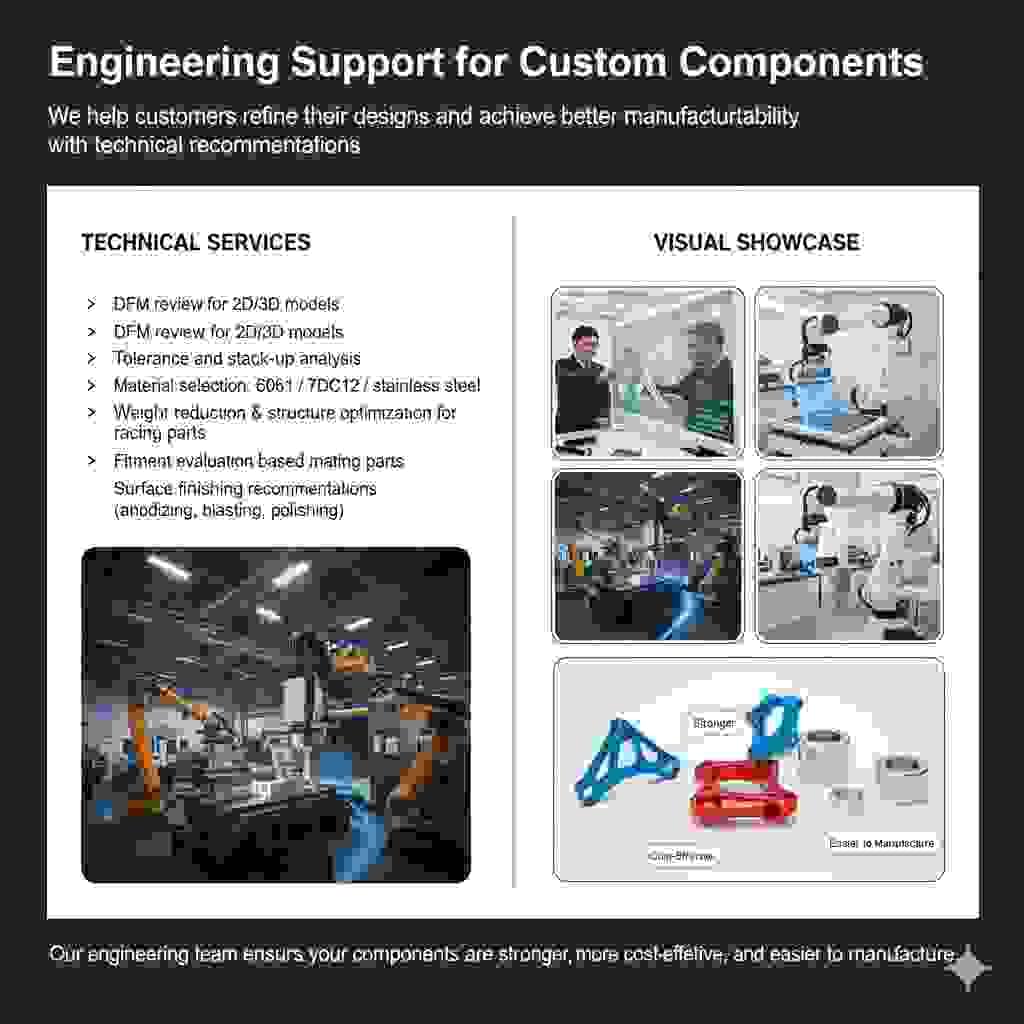

Engineering Support for Custom Components

We help customers refine their designs and achieve better manufacturability with technical recommendations.

➤ DFM review for 2D/3D models

➤ Tolerance and stack-up analysis

➤ Material selection: 6061 / 7075 / ADC12 / stainless steel

➤ Weight reduction & structure optimization for racing parts

➤ Fitment evaluation based on mating parts

➤ Surface finishing recommendations (anodizing, blasting, polishing)Our engineering team ensures your components are stronger, more cost-effective, and easier to manufacture.

CMM Inspection & Dimensional Accuracy Control

Precision matters for every custom component.

We use professional measurement tools to guarantee consistency and accuracy.➤ CMM inspection for critical dimensions

➤ Calipers, micrometers, height gauges

➤ Thread gauge tests (Go/No-Go)

➤ Flatness & concentricity checks

➤ Surface roughness testing

➤ Fitment testing with mating partsOur inspection ensures reliable and repeatable quality for every batch.

Our Quality-Controlled Manufacturing Workflow

1Drawing Review

2DFM Optimization

4In-Process Inspection

5Pre-Finishing Surface Check

6Anodizing / Surface Finishing

7Final QC & Thread Inspection

8Secure Packaging & Delivery

Surface Preparation & Anodizing Quality Control

High-quality anodizing starts with perfect surface preparation.

We focus on every detail to achieve consistent and premium finishing.➤ Sandblasting for matte texture

➤ Polishing for gloss finish

➤ Deburring & edge smoothing

➤ Masking for threads & functional areas

➤ Color consistency control

➤ Laser marking optionsPerfect preparation ensures beautiful and durable results.

Why Engineering & Quality Support Matters

Professional support helps your products succeed long-term.

➤ Lower machining and production cost

➤ Improved durability and strength➤ Faster development and time-to-market

➤ Fewer tolerance or assembly issues➤ Better anodizing and appearance

➤ Reduced scrap, rework, and customer complaintsNeed Engineering Review or CMM Inspection?

Send us your drawings or samples — we offer engineering feedback, tolerance suggestions, and full QC support from prototype to production.

OUR PRODUCTS

- Fuel & Cooling Caps

- Wheel Fasteners

- EV Component

- Control Parts

- Badges & Decorative Parts

- Quick Release & Racing Parts

CONTACT US

Email: lisa@

Tel: +86 13810563840

Whatsapp/Wechat:

+86 13810563840

News

OVER 20 YEARS OF EXPERIENCE IN ALUMINUM PARTS

Global Export Capability | Fast Response | OEM/ODM Ready | Engineering Support

Wometal is a manufacturer of CNC machined and die-cast aluminum components for automotive, racing, motorcycle and EV applications.

We produce custom aluminum parts including fuel caps, engine covers, spacers, reservoir caps, cooling caps and precision components for global brands and aftermarket companies.