Auto & Motor Parts

- …

Auto & Motor Parts

- …

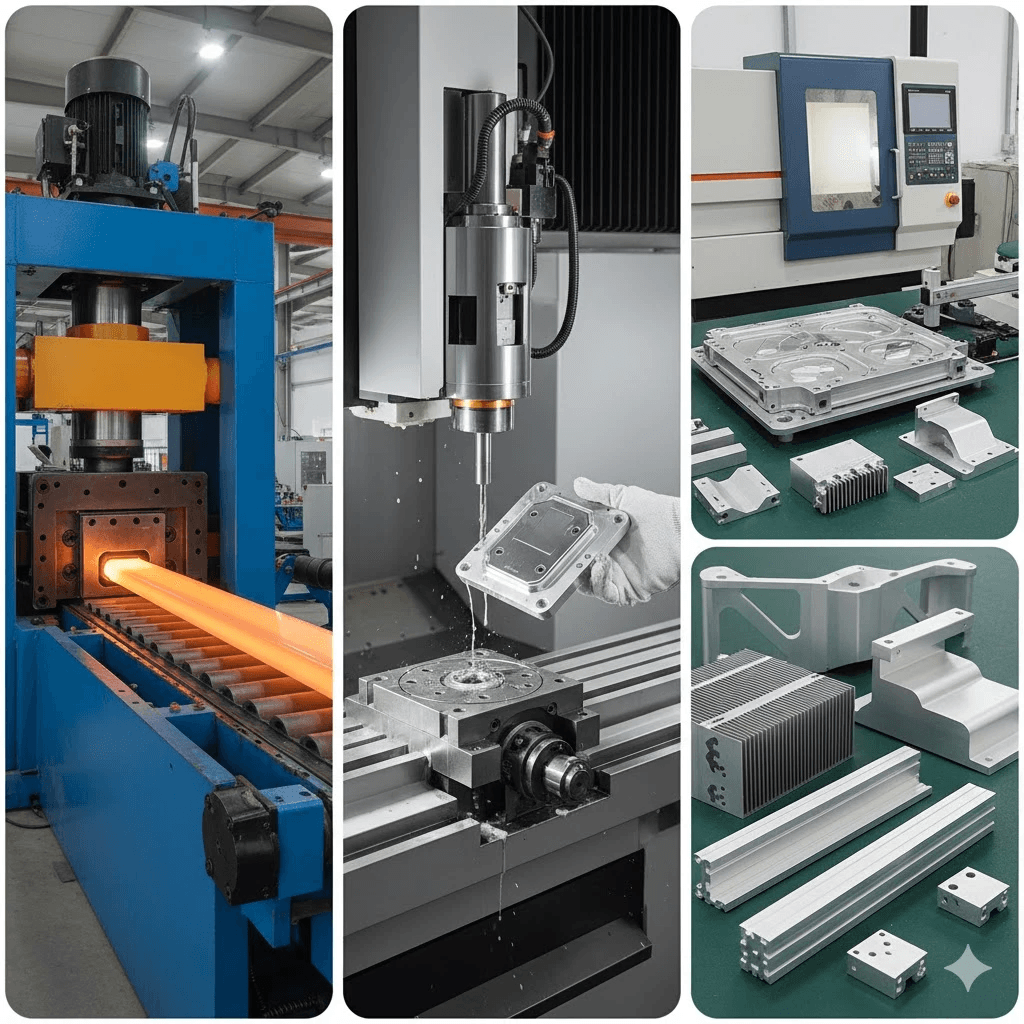

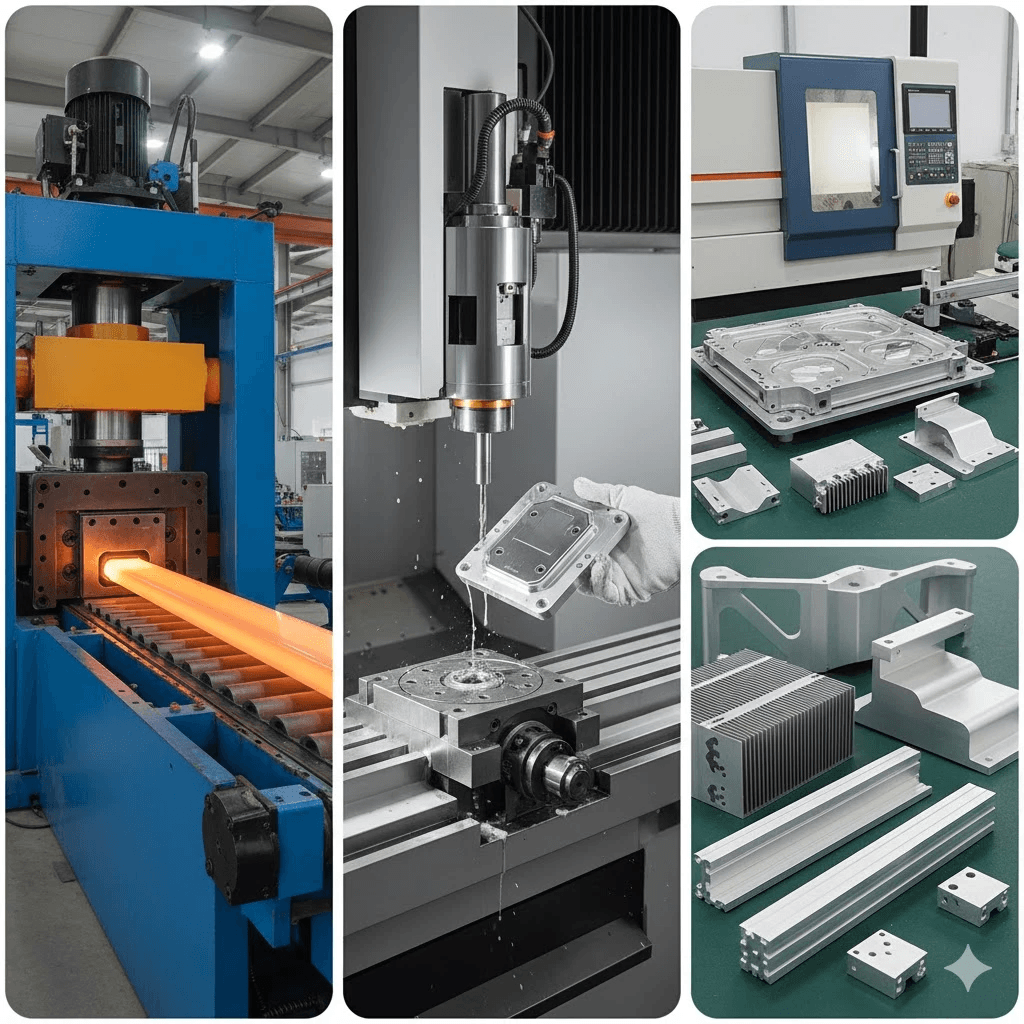

Aluminum Extrusion for Stable and Cost-Effective Cooling Solutions

Engineering-driven aluminum extrusion for EV, automotive, and energy-related applications. Aluminum extrusion is often the most robust manufacturing solution when geometry allows.

It is widely used in applications that prioritize long-term stability, consistency, and cost efficiency over peak performance.

Why Aluminum Extrusion Makes Engineering Sense

Aluminum extrusion is not about maximum design freedom — it is about predictability and scalability.

Extrusion is especially suitable when:

- Long, straight profiles are acceptable

- Production volume is medium to high

- Consistency and repeatability are critical

- Cost control at scale matters

In many thermal and structural applications, extrusion provides the best balance between performance, stability, and manufacturability.

Extrusion Applications by Product Category

This section explains how Aluminum extrusion is applied across different product categories, and where engineering caution is required.

Aluminum extrusion is selectively applied in EV systems, mainly for non-safety-critical or semi-structural cooling components.

Typical extruded EV parts include:

- Cooling-related structural profiles

- Auxiliary thermal management components

- Support structures with straight internal channels

Engineering considerations for EV:

- Suitable when geometry is simple and inspectable

- Often combined with CNC post-machining for interfaces and sealing

- Not typically used for safety-critical battery cold plates

In automotive applications, aluminum extrusion is widely used for structural and thermal profiles.

Typical extruded automotive parts include:

- Heat dissipation profiles

- Structural rails and supports

- Functional aluminum sections requiring consistency at scale

Why extrusion for automotive components:

- Excellent dimensional consistency

- Competitive cost for volume production

- Stable material properties

Aluminum extrusion has limited application in motorcycle and racing components.

Typical usage scenarios:

- Structural or support profiles

- Parts without complex geometry or aesthetic requirements

Engineering note:

- Performance and racing parts usually prioritize CNC machining for precision and appearance

- Extrusion is mainly used where function and consistency outweigh customization

Engineering Considerations for Extruded Aluminum Parts

- What Engineers Evaluate Before Choosing Extrusion

- Cross-section must be extrusion-feasible

- Internal channels are typically straight and open

- Secondary CNC machining is often required for:

- Sealing surfaces

- Mounting interfaces

- Assembly features

- Design should allow for inspection and maintenance

Extrusion defines geometry — design must respect the process, not fight it.

Extrusion vs CNC vs Die Casting (Engineering View)

To better understand how engineers choose between aluminum extrusion, CNC machining, and die casting for cooling components, you may find this article helpful:

👉 CNC vs Die Casting vs Extrusion for Aluminum Cooling Components.

Extrusion Capability & Engineering Strength

Our aluminum extrusion capability is built for engineering-grade thermal and structural applications — not commodity profiles.

Key extrusion capabilities include:

- Aluminum extrusion profiles with straight internal channels

- Medium to large cross-section profiles suitable for thermal management

- Stable dimensional control for long-length parts

- Material options commonly used for thermal applications (e.g. 6061, 6063)

Engineering advantages of our extrusion solutions:

- Close collaboration between extrusion and CNC machining

- Post-machining of critical features such as:

- Sealing surfaces

- Mounting interfaces

- Assembly references

- Design support to ensure extrusion-feasible geometry from early stages

Quality & consistency focus:

- Emphasis on repeatability for medium to high-volume production

- Dimensional verification after extrusion and secondary machining

- Engineering review for inspectability and long-term reliability

Our extrusion capability is designed to support real-world production — not just profile manufacturing.

Why Choose Wometal Aluminum Extrusion

We combine engineering expertise, precision equipment, and strict quality control to deliver reliable Aluminum Extrusion solutions for automotive and EV components.

One-Stop Production

From mold design, casting, machining, to finishing in one facility.

High Consistency

Tight process control and automated production lines.

Material Expertise

Aluminum ADC12, A380, and custom alloys available.

Engineering Support

DFM and mold optimization for manufacturability.

Quality Assurance

100% dimensional inspection and surface testing.

When Extrusion Is the Right Choice — and When It Is Not

Recommended When:

- Long-term stability is prioritized

- Production volume justifies tooling

- Geometry is simple and repeatable

- Cost efficiency is a key requirement

Not Recommended When:

- Complex internal flow paths are required

- Zero-leakage or safety-critical functions are involved

- High aesthetic or customization demand exists

In such cases, CNC machining or hybrid solutions may be more appropriate.

Not Sure If Extrusion Fits Your Design?

Share your application requirements and system constraints.

We’ll review your design from an engineering and manufacturability perspective — not just from a process capability standpoint.

OUR PRODUCTS

- Fuel & Cooling Caps

- Wheel Fasteners

- EV Component

- Control Parts

- Badges & Decorative Parts

- Quick Release & Racing Parts

CONTACT US

Email: lisa@

Tel: +86 13810563840

Whatsapp/Wechat:

+86 13810563840

News

OVER 20 YEARS OF EXPERIENCE IN ALUMINUM PARTS

Global Export Capability | Fast Response | OEM/ODM Ready | Engineering Support

Wometal is a manufacturer of CNC machined and die-cast aluminum components for automotive, racing, motorcycle and EV applications.

We produce custom aluminum parts including fuel caps, engine covers, spacers, reservoir caps, cooling caps and precision components for global brands and aftermarket companies.