Auto & Motor Parts

- …

Auto & Motor Parts

- …

Custom Motorcycle & Racing Components Manufacturer

Precision CNC Machined & Billet Aluminum Parts for Performance Bikes

What We Make

High-Performance Motorcycle & Racing Aluminum Components

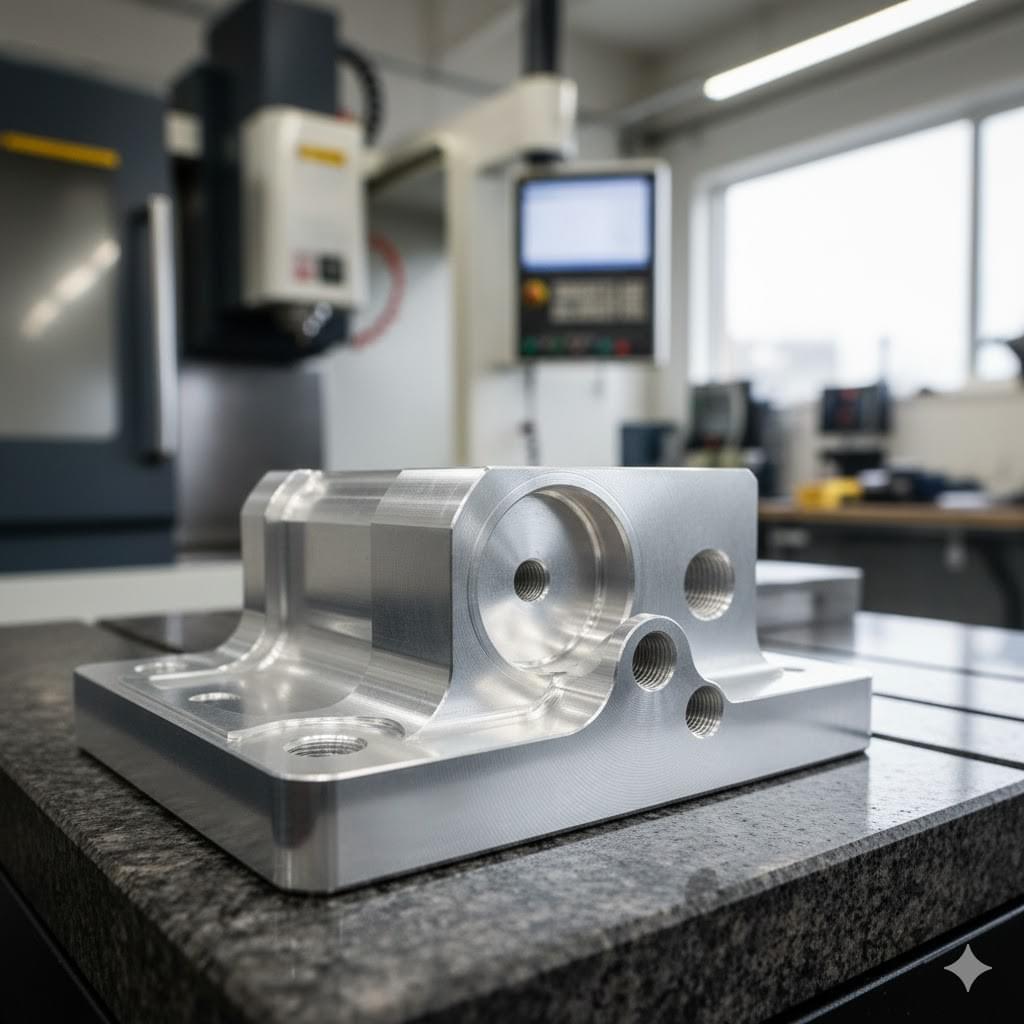

CNC Motorcycle Parts

Precision-machined aluminum components with ±0.02 mm tolerance.

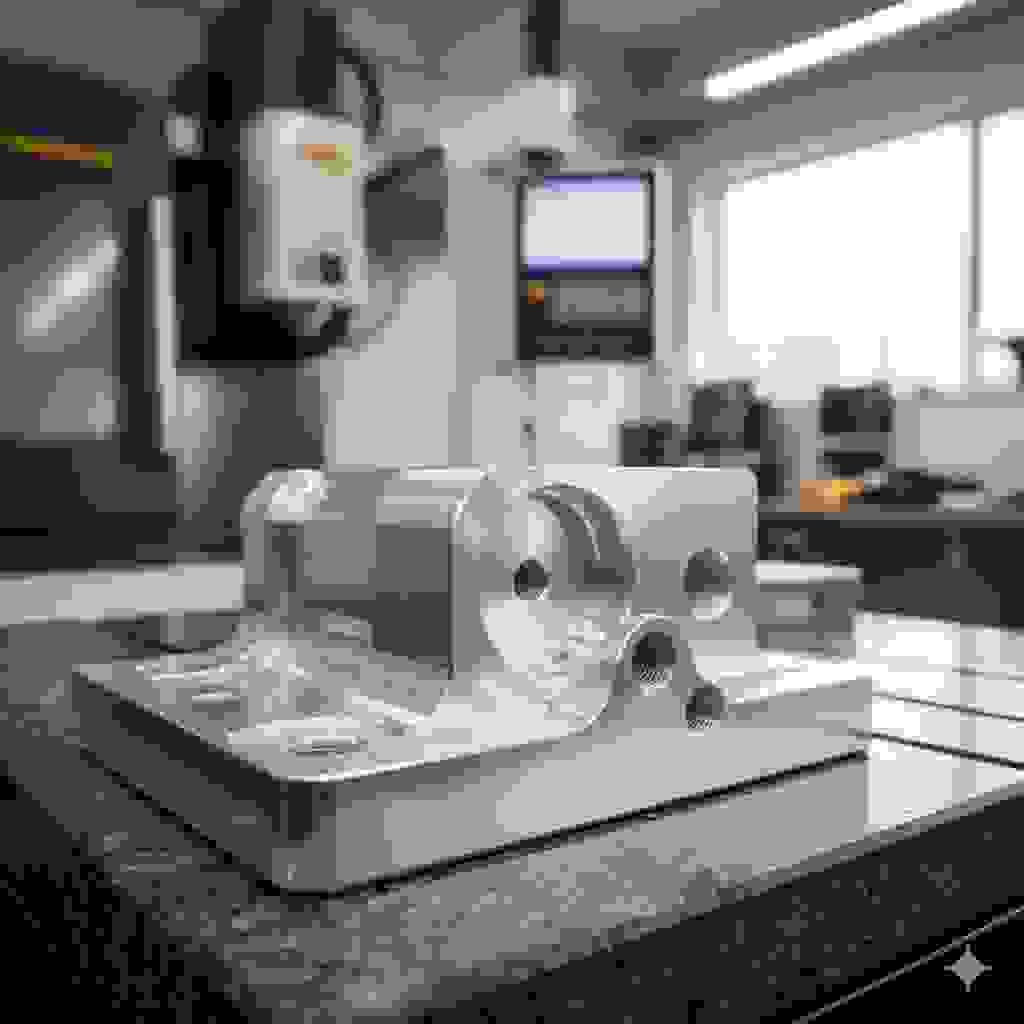

Billet Aluminum Motorcycle Parts

Strong, lightweight billet components ideal for performance and racing.

Fuel Caps & Quick-Release Caps

CNC aluminum fuel caps engineered for durability and fast operation.

Wheel Spacers & Axle Spacers

Accurate spacers ensuring proper alignment and improved stability.

Brake & Reservoir Caps

Billet reservoir covers for brake and clutch systems.

Radiator Caps / Cooling Caps

High-pressure aluminum caps designed for reliable cooling performance.

Engine Covers & Protection Covers

Durable CNC aluminum covers for engine protection and aesthetics.

Handlebar Risers & Bar Ends

Machined risers and bar-end components for improved control.

Oil Caps & Tank Caps

Stylish and durable CNC aluminum oil and tank caps.

Why Aluminum

Why Aluminum Is the Best Material for Motorcycle & Racing Components.

Lightweight but Strong

Aluminum reduces weight without sacrificing structural strength, improving speed, handling, and acceleration.

Perfect for CNC Precision

6061-T6 and 7075-T6 aluminum allow highly accurate machining, making them ideal for complex racing components.

Excellent Heat & Corrosion Resistance

Aluminum performs well under high temperatures and harsh environments, essential for racing and performance bikes.

Anodized Surface for Color & Protection

Anodizing offers strong corrosion resistance and multiple color options like gold, blue, red, and black.

Ideal for Custom & Small-Batch Production

Aluminum is easy to machine and finish, making it perfect for custom parts, prototypes, and low-volume runs.

Our Manufacturing Capabilities

CNC Machining (3-axis, 4-axis, 5-axis)

We manufacture high-precision motorcycle and racing components with ±0.02 mm tolerance, using multi-axis machining centers for complex billet aluminum parts.

Materials: 6061-T6 & 7075-T6 Aluminum

We work with aerospace-grade aluminum to achieve the strength, lightweight performance, and machinability required for racing applications.

Surface Finishing & Anodizing

We offer full anodizing options including black, red, blue, gold, silver, and custom colors. Every surface is finished for smoothness, corrosion resistance, and visual performance.

CMM Measurement & Quality Inspection

Every part is inspected for dimensions, surface finish, thread quality, and assembly fit. CMM and digital measuring tools ensure consistent accuracy.

Small Batch & Custom Production

We support prototypes, racing teams, customization brands, and low-volume production. Perfect for new designs, special editions, and performance upgrades.

Our Process

1Send Drawings or Samples

2Engineering Review

3Quotation & DFM Suggestions

4Material Preparation(6061 / 7075)

5Die Casting / CNC Machining

6Surface Finishing & Anodizing

7Inspection & Testing (CMM / QC)

8Packing & Delivery

Quality & Inspection

Quality Control & Inspection for Every Motorcycle Component

Dimensional Accuracy Check (CMM & Digital Measurements)

Every critical dimension is inspected using CMM machines, digital calipers, thread gauges, and custom fixtures to ensure accuracy and repeatability.

Surface Finish & Tool Mark Inspection

We examine surface roughness, tool patterns, chamfers, threads, and edges to ensure each part meets visual and functional requirements.

Material & Hardness Verification

Aluminum grades (6061 / 7075) and hardness levels are verified to ensure the strength and durability required for racing components.

Assembly Fit & Functional Testing

Key parts such as caps, spacers, and covers are tested for fitment, sealing performance, and compatibility with mating components.

Customer Success Stories

Customer Success Stories Across Motorcycle, Racing, and Commercial Vehicles

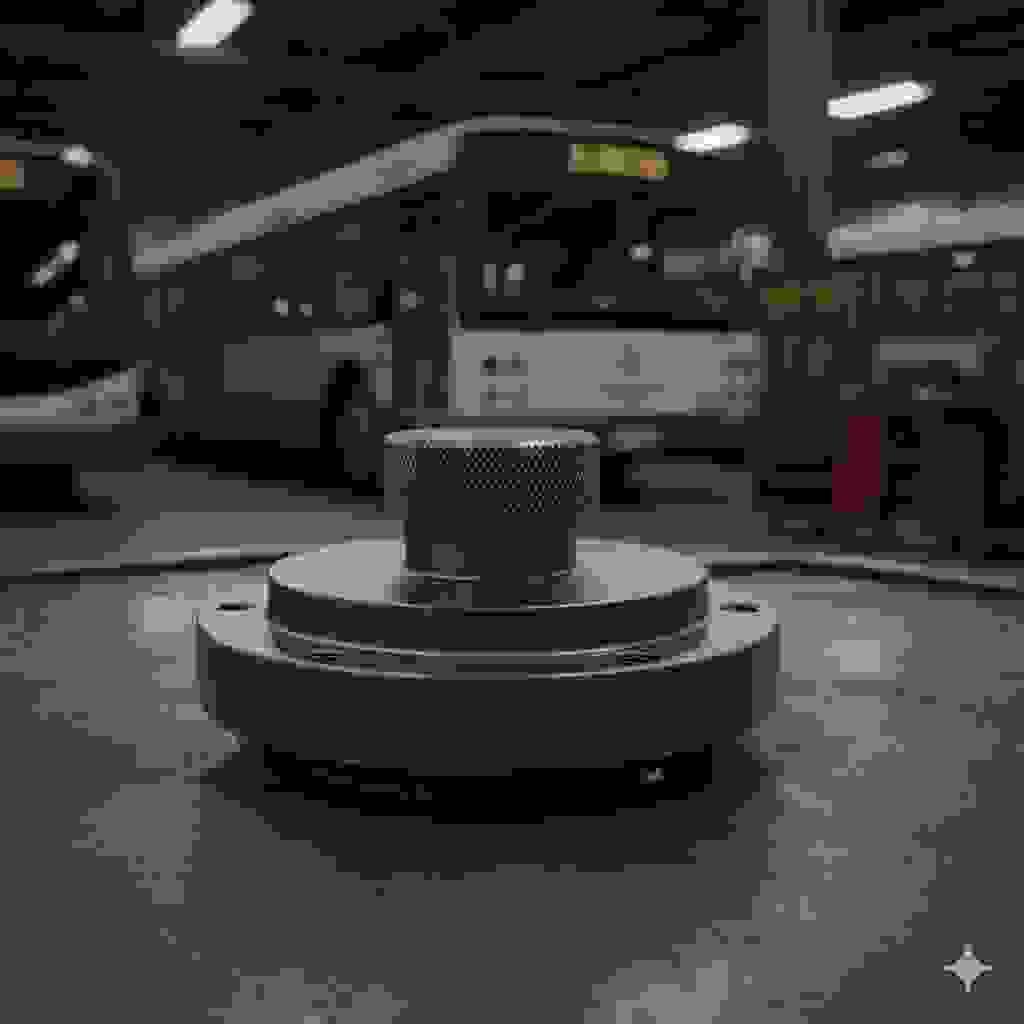

Heavy-Duty Fuel Tank Cap for City Bus Fleet

A bus operator required a stronger and more durable aluminum fuel tank cap to replace their original cast parts, which frequently cracked under vibration.

We redesigned the structure using 6061-T6 billet aluminum, improved the threading fit, and applied hard anodizing to increase wear resistance.

The new parts have been running for over 2 years with zero failures.

CNC Engine Cover for Performance Motorcycle Brand

A motorcycle aftermarket brand needed a precisely machined engine cover with tight tolerances for perfect fitment.

We produced a prototype in 5 days using 7075-T6 aluminum, CNC-machined with ±0.02 mm accuracy, added chamfer polishing, and delivered anodized samples in black and gold.

The brand proceeded with small-batch repeat orders.

Quick Release Fuel Cap for Racing Team

A racing team required a quick-release fuel cap optimized for fast refueling and durability.

We optimized the internal locking structure, used 7075 aluminum for strength, and produced color-anodized components for team branding.

The parts performed reliably through multiple race events.FAQs

Frequently Asked Questions

1. Can you manufacture custom motorcycle parts from my drawings?

2. What materials do you use for motorcycle and racing components?

3. What is your typical machining tolerance?

4. Can you provide anodizing and custom colors?

5. What is your MOQ for custom parts?

6. How long is the lead time?

7. Can you help improve my design (DFM)?

8. Do you ship worldwide?

Ready to Start Your Motorcycle or Racing Parts Project?

Tell us what you need — we’ll help you make it happen.

Related Articles

CNC machined motorcycle parts — such as fuel caps, engine covers, spacers, and racing components ...Anodizing is one of the most important surface treatments for aluminum motorcycle components. It...Many brands, distributors, and aftermarket companies want custom motorcycle components — whether...Racing components are not the same as standard motorcycle parts. They need: Higher strengthLower...November 19, 2025When sourcing CNC-machined or billet aluminum motorcycle components, quality inspection is one of...November 19, 2025Choosing the right motorcycle parts supplier is one of the most important decisions for brands,...November 19, 2025When motorcycle brands, racing teams, and aftermarket companies source components, one of the...Aluminum has become the preferred material for modern motorcycle and racing components. Whether...When sourcing high-quality motorcycle components, buyers often struggle to decide between CNC...November 17, 2025Motorcycle component sourcing can be confusing—especially for buyers who need custom or high...March 3, 2023Motorcycle gas cap Motorcycles are an iconic symbol of freedom and the open road, but they...

OUR PRODUCTS

- Fuel & Cooling Caps

- Wheel Fasteners

- EV Component

- Control Parts

- Badges & Decorative Parts

- Quick Release & Racing Parts

CONTACT US

Email: lisa@

Tel: +86 13810563840

Whatsapp/Wechat:

+86 13810563840

News

OVER 20 YEARS OF EXPERIENCE IN ALUMINUM PARTS

Global Export Capability | Fast Response | OEM/ODM Ready | Engineering Support

Wometal is a manufacturer of CNC machined and die-cast aluminum components for automotive, racing, motorcycle and EV applications.

We produce custom aluminum parts including fuel caps, engine covers, spacers, reservoir caps, cooling caps and precision components for global brands and aftermarket companies.