As global automakers push toward carbon neutrality, the way we design and manufacture automotive components is transforming.

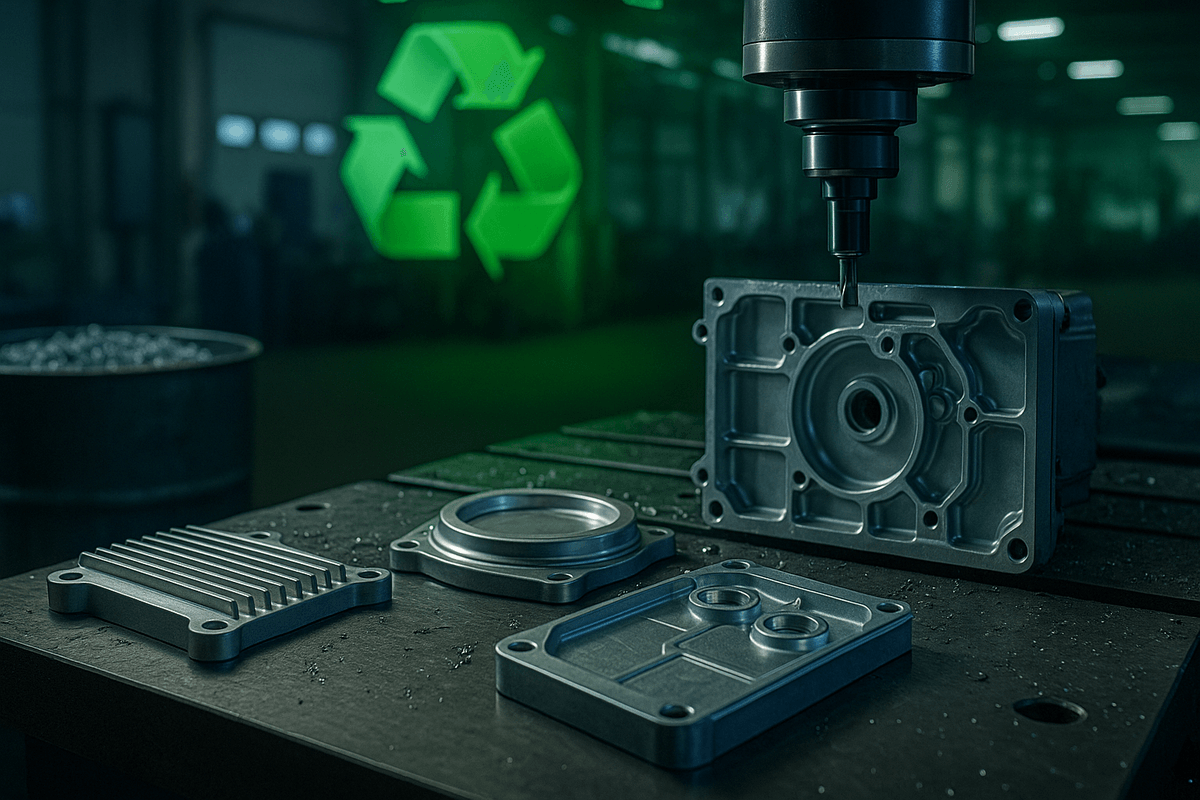

From recycled aluminum to energy-efficient CNC machining, sustainable manufacturing is reshaping how suppliers, like Wometal, create smarter, cleaner, and lighter products for modern vehicles.

1. The Global Shift Toward Sustainability

The automotive industry is undergoing one of its biggest transitions in history — reducing emissions not only from vehicles but also from the manufacturing process itself.

OEMs now require suppliers to:

- Use recycled and traceable materials

- Lower energy consumption per part

- Reduce waste and emissions in production

- Provide environmental compliance documents (RoHS, REACH, ISO 14001)

At Wometal, sustainability isn’t just a trend — it’s part of our daily manufacturing workflow.

2. Why Aluminum Is Key to Sustainable Automotive Design

Aluminum is at the heart of green automotive design.

It’s lightweight, corrosion-resistant, and — most importantly — infinitely recyclable.

Key sustainability benefits:

- Recycling aluminum saves up to 95% of energy compared to producing new material

- Reduces CO₂ emissions per component

- Maintains full strength and performance after multiple recycling cycles

That’s why aluminum is now used widely in battery housings, cooling systems, and structural components across both fuel and electric vehicles.

3. Energy-Efficient Manufacturing Processes

Sustainability isn’t only about materials — it’s also about how we make them.

Modern CNC machining and die casting can be optimized to save both time and energy.

At Wometal, we implement:

- High-speed CNC machining with optimized tool paths to reduce idle time

- Smart scheduling systems to minimize energy peaks

- Recycling of metal chips and cutting fluids

- Energy-efficient furnaces for die casting aluminum components

This helps us maintain precision and quality while cutting waste and carbon emissions.

4. Water and Waste Reduction

Manufacturing can consume large amounts of water and create waste — unless it’s properly managed.

Our production systems are designed to minimize impact through:

- Closed-loop water circulation for cooling systems

- Filtration and recycling of cutting fluids

- Responsible disposal of metal waste

- Separation and reuse of aluminum scrap

Sustainability is achieved not only through innovation but also through discipline in every detail of production.

5. Sustainable Surface Finishing

Many automotive components require surface finishing — anodizing, coating, or polishing — which can impact the environment.

Wometal works with partners using low-VOC, non-toxic, and water-based finishing processes, ensuring compliance with EU environmental standards.

Our focus:

- Water-based anodizing

- Powder coating with minimal waste

- Chrome-free conversion coatings

6. Supply Chain Transparency and Traceability

Modern customers care about where and how parts are made.

We provide full transparency with:

- Material batch traceability

- Digital inspection reports (PPAP, FAI)

- Sourcing from certified suppliers only

- Recycled material documentation

This helps our partners prove environmental compliance while maintaining performance and cost efficiency.

7. Wometal’s Commitment to Sustainable Manufacturing

At Wometal, we believe that precision and sustainability can go hand in hand.

Our facilities integrate:

- Energy-efficient CNC machining and die casting

- Recycling of aluminum waste

- Eco-friendly finishing processes

- Documentation for RoHS, REACH, ISO 9001, and ISO 14001 compliance

By continuously improving our workflow, we help customers meet their environmental goals — without compromising quality or performance.

Conclusion

Sustainability isn’t just the future of automotive manufacturing — it’s already here.

From lightweight aluminum to efficient production and recycling, every step toward sustainability makes vehicles safer, greener, and more efficient.

At Wometal, we’re proud to be part of that evolution, creating automotive components that perform better — and impact less.

👉 “Learn more about our automotive components.