Auto & Motor Parts

- Resources

- …

- Resources

Auto & Motor Parts

- Resources

- …

- Resources

EV & New Energy Components: Battery Housing, Cooling Plates & Aluminum Enclosures

High-precision CNC & die-cast aluminum parts for electric vehicles, battery packs, and energy-storage systems.

What We Manufacture

Battery Housing Manufacturing

Lightweight and high-strength aluminum housings for EV battery packs and energy-storage modules.

Liquid Cooling Plates (Thermal Management)

Machined cooling plates and thermal components for battery thermal management.

Precision CNC Machining

Tight-tolerance machining for aluminum EV components and structural parts.

Energy Storage Aluminum Components

Custom enclosures and brackets for ESS and high-voltage systems.

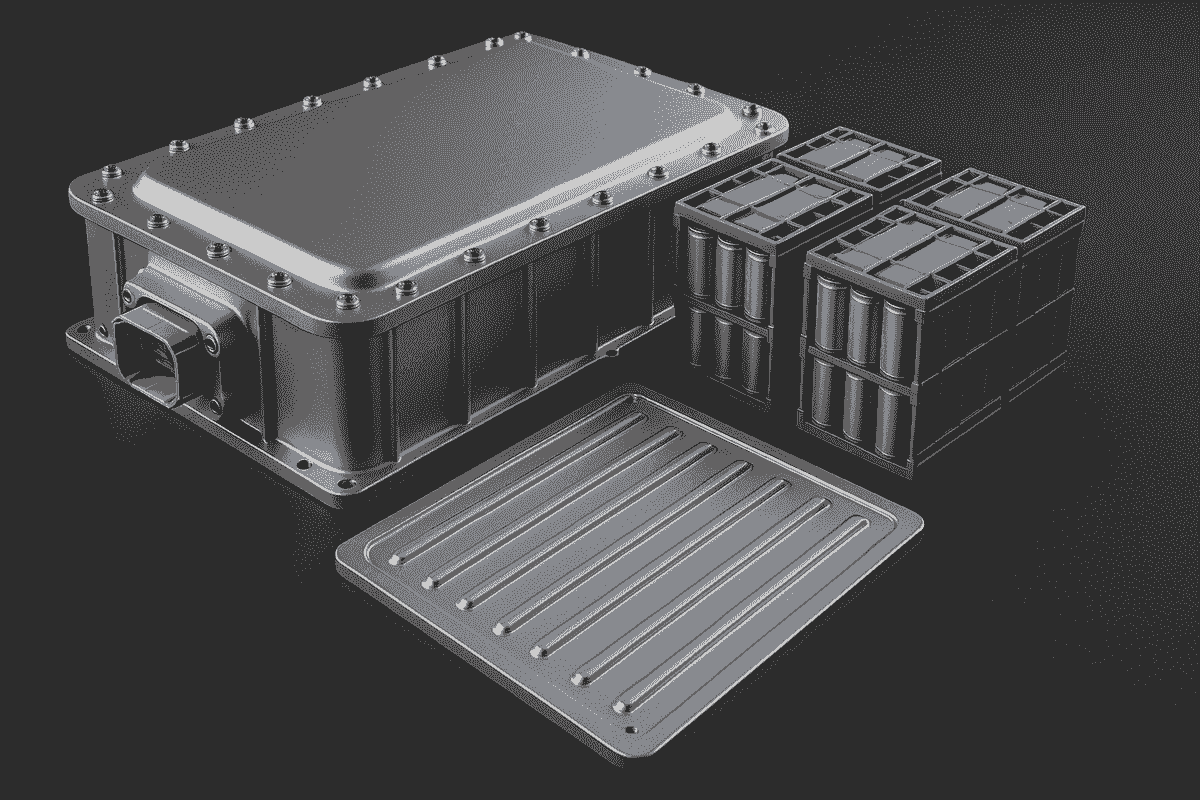

Aluminium Battery Housing & Pack Enclosures

We manufacture aluminum battery housings for EV battery packs and energy-storage systems.Our process combines CNC machining, die-casting, and surface finishing to achieve strength, sealing reliability, and lightweight performance.

- Custom CNC or die-cast aluminum housings

- Reinforced structures with reduced wall thickness

- Tight-tolerance sealing surfaces

- Waterproof interface optimization

- Corrosion-resistant anodizing

- Small-batch prototype → mass production

- CMM inspection for critical dimensions

Liquid Cooling Plates & Thermal Management Components

Thermal management is essential for EV battery safety and performance.

We produce high-precision liquid cooling plates with consistent flow channels and excellent heat-transfer performance.- Machined aluminum cooling channels

- Bonded / welded / CNC monoblock plates

- 6061 or 3003 aluminum options

- Micro-channel design capabilities

- Leak-proof sealing surfaces

- Surface finishing to prevent corrosion

- Compatibility with EV and ESS batteries

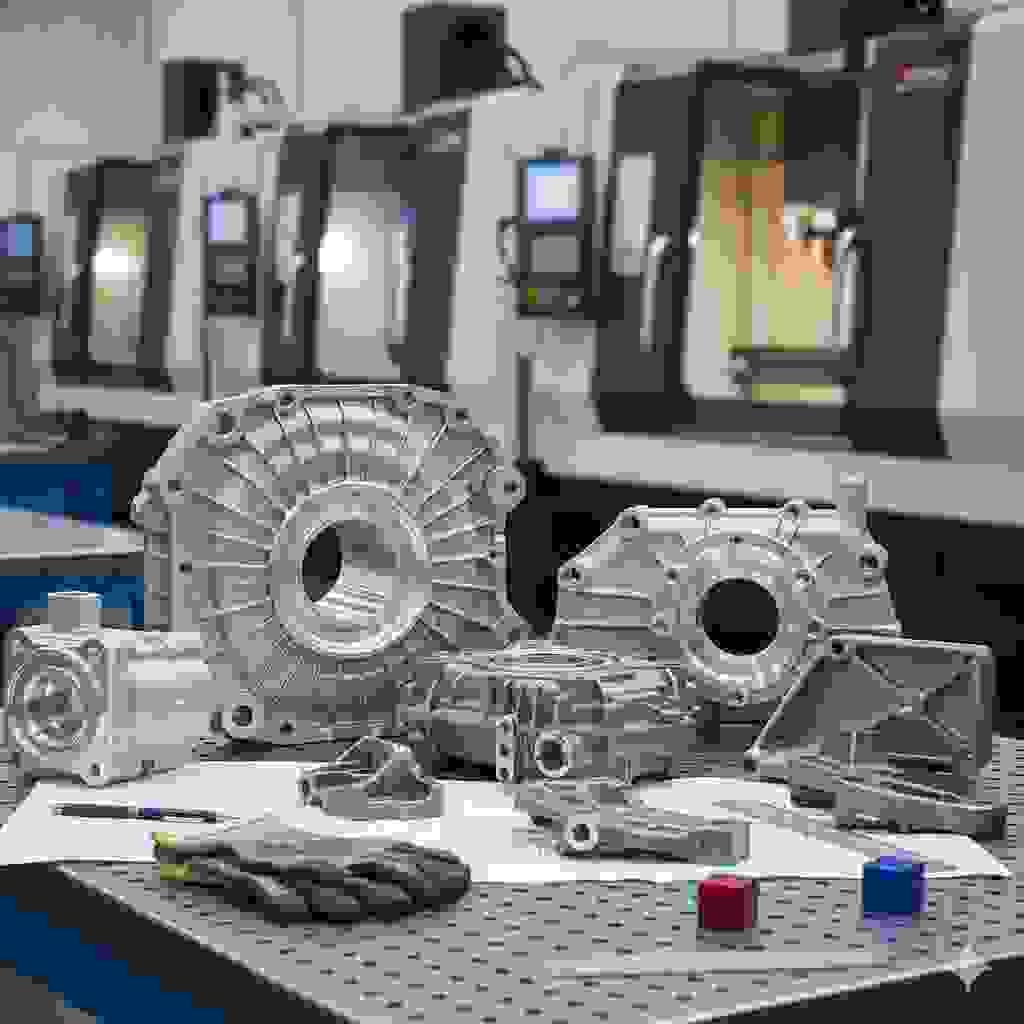

Die-Cast & Machined Aluminum EV Components

We supply die-cast aluminum parts with precision machining for EV power electronics and structural modules.

- ADC12 / A380 aluminum die-casting

- CNC finishing for sealing and assembly areas

- Inverter housings, controller cases, motor enclosures

- High-strength, lightweight structural components

- Consistent quality from prototype to full production

Our Manufacturing Capabilities

Precision CNC Machining

5-axis, 3-axis, turning, high-accuracy milling for EV parts.

Die-Casting & Finishing

Low-volume and high-volume die-cast aluminum components.

Surface Finishing

Anodizing, blasting, polishing, hard anodizing, laser marking.

Assembly Fitment Checks

Battery module fitment, sealing evaluation, cooling path accuracy.

Engineering Support

DFM review, tolerance analysis, thermal optimization guidance.

Quality Inspection

CMM, thread gauges, flatness measurement, surface checks.

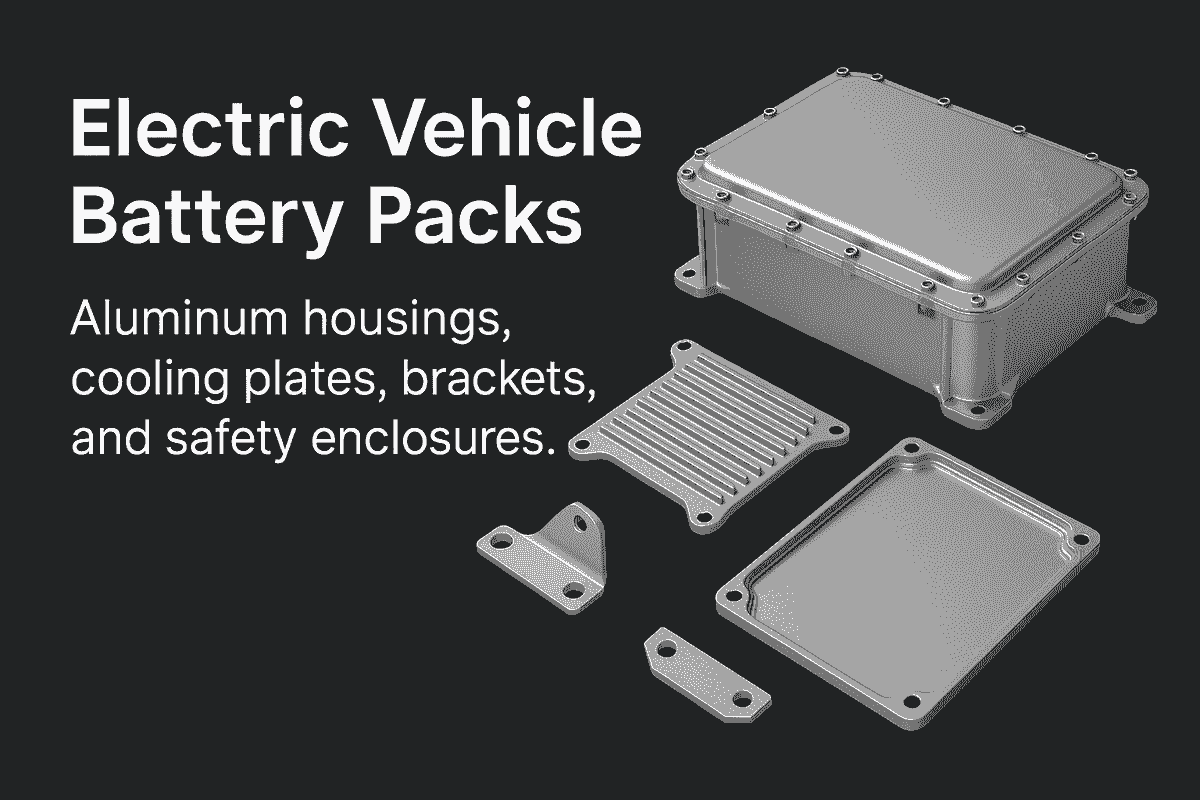

Applications in EV & Energy Storage

Electric Vehicle Battery Packs

Aluminum housings, cooling plates, brackets, and safety enclosures.

Energy Storage Systems (ESS)

Battery pack enclosures, cooling components, and structural aluminum parts.

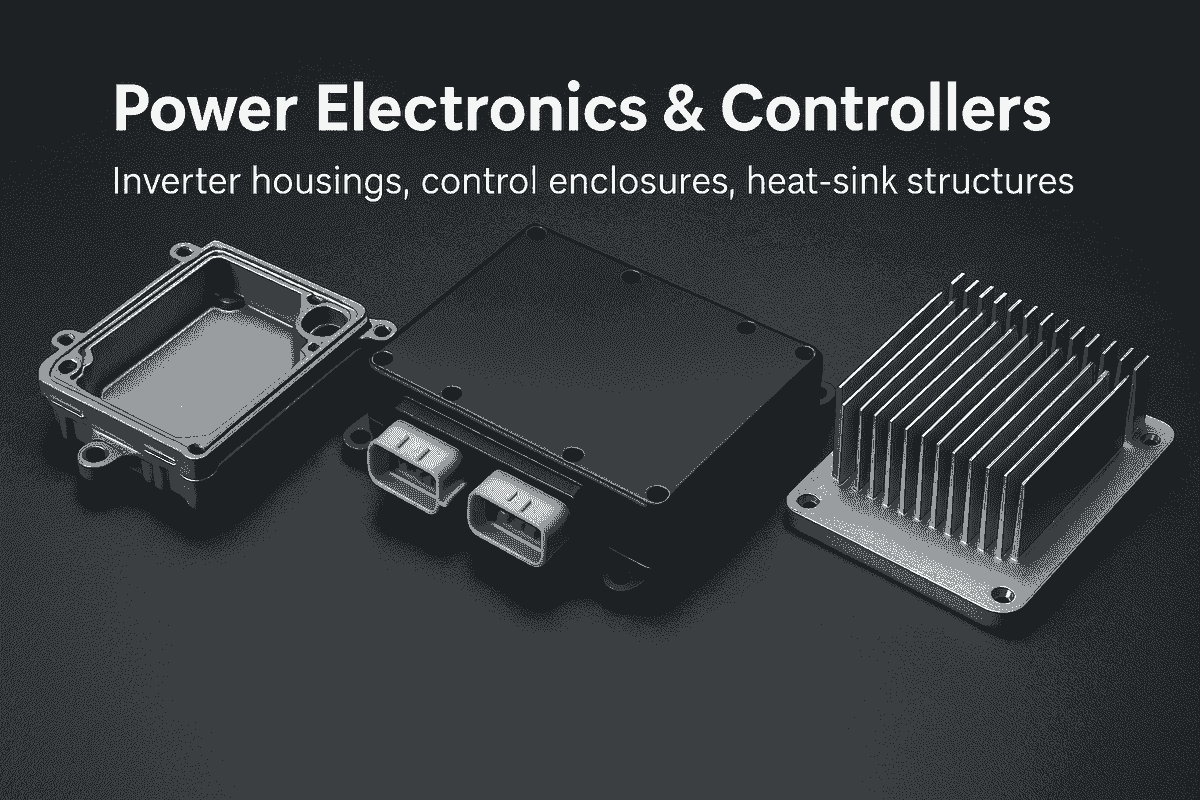

Power Electronics & Controllers

Inverter housings, control enclosures, heat-sink structures.

Engineering & Quality Support

Our engineering team ensures manufacturability, consistency, and performance in every EV component.

- DFM review for battery housings and cooling plates

- Thermal performance guidance for channel design

- Tolerance optimization & machining strategy

- CMM inspection for critical dimensions

- Surface and sealing quality verification

- Repeatable color and finish control

Why Companies Choose Us

EV Aluminum Components Specialist

Battery housings & cooling plate expertise.

High-Precision Manufacturing

Stable tolerances for sealing & fitment.

Full QC Inspection

CMM, thread gauges, flatness, surface consistency.

Prototyping → Mass Production

Fast lead times with flexible capacity.

Need Aluminum Components for EV or Energy Storage?

Send us your drawings for engineering review, DFM support, and rapid manufacturing.

EV Engineering Insights & Technical Guides

Expert articles on battery housings, cooling plates, thermal management, and aluminum enclosure manufacturing — helping EV engineers and buyers make better decisions.

November 25, 2025Introduction Choosing the right EV aluminum components is no longer just about price or...Introduction As electric vehicles (EVs) continue to evolve, the components inside battery packs...November 25, 2025Introduction Energy Storage Systems (ESS) are becoming a core technology for renewable energy,...Introduction Whether it’s a liquid cooling plate, battery housing, or thermal-management...Introduction As EV battery systems, power electronics, and thermal-management components become...Introduction EV battery housings are one of the most critical components in the entire battery...Introduction Electric vehicle (EV) battery packs and power-electronics modules require...Introduction As EV battery systems become more powerful and energy-dense, thermal management is...Introduction Aluminum battery housings are one of the most critical structural components in...

OUR PRODUCTS

- Fuel & Cooling Caps

- Wheel Fasteners

- EV Component

- Control Parts

- Badges & Decorative Parts

- Quick Release & Racing Parts

CONTACT US

Email: lisa@

Tel: +86 13810563840

Whatsapp/Wechat:

+86 13810563840

News

OVER 20 YEARS OF EXPERIENCE IN ALUMINUM PARTS

Global Export Capability | Fast Response | OEM/ODM Ready | Engineering Support

Wometal is a manufacturer of CNC machined and die-cast aluminum components for automotive, racing, motorcycle and EV applications.

We produce custom aluminum parts including fuel caps, engine covers, spacers, reservoir caps, cooling caps and precision components for global brands and aftermarket companies.